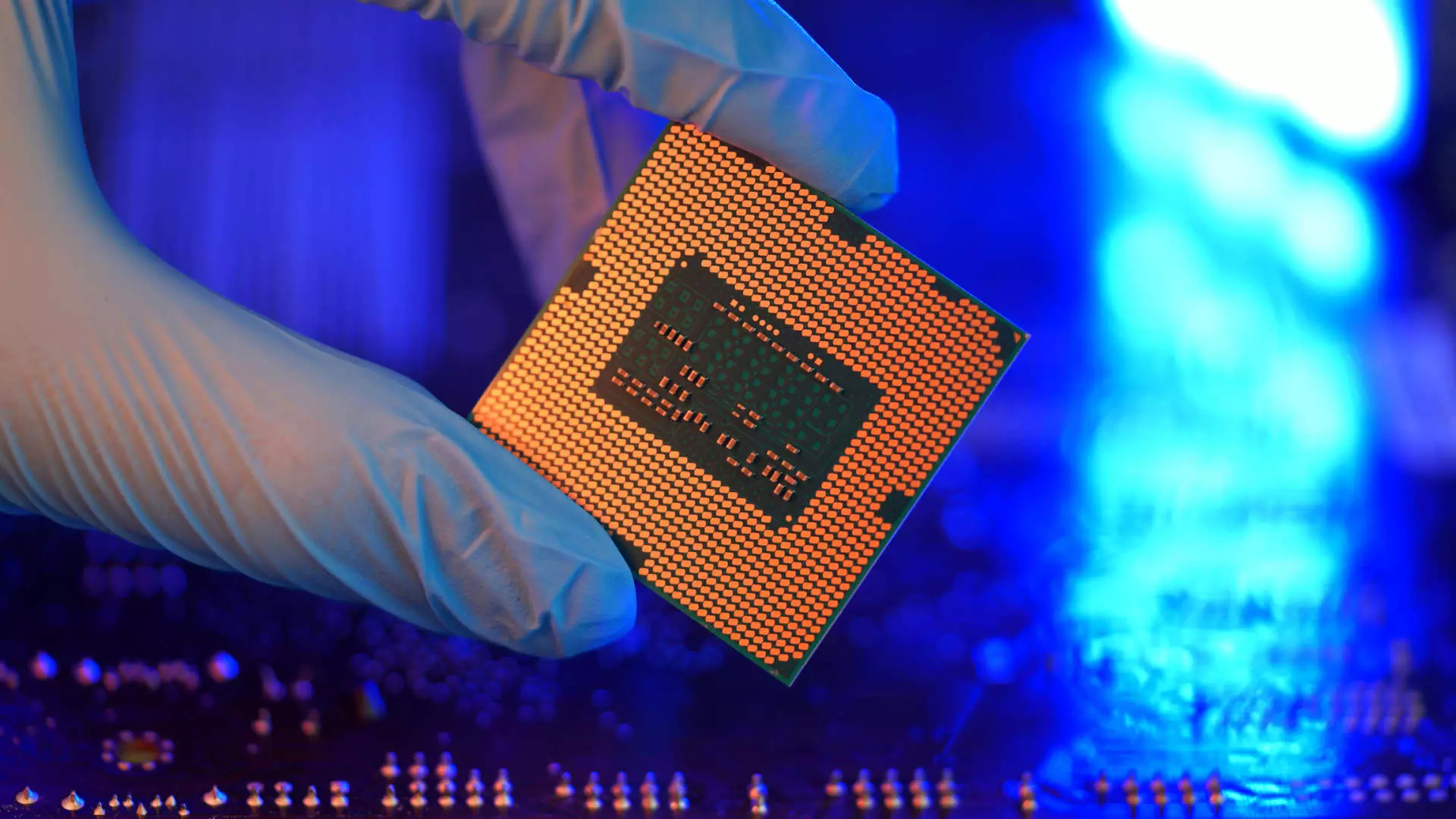

The semiconductor industry, led by giants like Taiwan Semiconductor Manufacturing Company (TSMC), is facing a looming crisis in the form of water shortages. As technological advancements continue to push the boundaries of processing capabilities, the demand for water in chip manufacturing processes is ever-increasing. Semiconductor chips, which are integral components of devices ranging from smartphones to TVs, require copious amounts of water for cooling machinery and ensuring clean wafer sheets.

S&P Global Ratings’ report highlights the direct correlation between water consumption and chip sophistication. Fabrication facilities (fabs) utilize ultrapure water to rinse wafers between each process step, with more advanced semiconductors necessitating a higher number of process steps and consequently, more water consumption. TSMC’s transition to 16-nanometer process nodes in 2015 led to a significant increase of over 35% in water consumption per unit, underscoring the escalating demand for water in tandem with technological progress.

Impact on Global Tech Supply Chain

The potential risks associated with water-related disruptions to semiconductor operations extend beyond TSMC to the entire global tech supply chain. S&P warns that any interruptions in TSMC’s operations could reverberate throughout the industry, given the company’s dominance in advanced chip manufacturing. However, TSMC’s market position and pricing power may mitigate the impact of output volatility, allowing the company to preserve its business profile and profitability in the face of challenges.

Strategies for Mitigating Water-Related Risks

In response to the escalating water crisis, semiconductor firms like TSMC may need to adopt strategic measures to navigate the challenges ahead. One possible avenue is a shift towards producing more advanced chips, which typically yield higher margins, in times of limited water supply. By focusing on high-value chip manufacturing, companies could potentially offset the adverse effects of water shortages on their bottom line.

The semiconductor industry is projected to witness a continued rise in water consumption, fueled by capacity expansions and technological advancements. S&P’s report forecasts an annual increase of mid- to high-single-digit percentages in water usage, reflecting the industry’s growing reliance on water resources. The magnitude of water consumption by chipmakers, already comparable to a city the size of Hong Kong, underscores the pressing need for sustainable water management practices.

Water security is poised to become a critical factor shaping the credit profiles of semiconductor firms in the coming years. Mishandling of water resources could not only disrupt operations and impair financial performance but also jeopardize key customer relationships. As the industry grapples with the challenges of water scarcity, proactive measures and strategic planning will be essential to ensure the long-term sustainability of semiconductor manufacturing.